FINCHER HOMOGENISING & COOLING SYSTEM

FINCHER HOMOGENISING & COOLING SYSTEM

Description

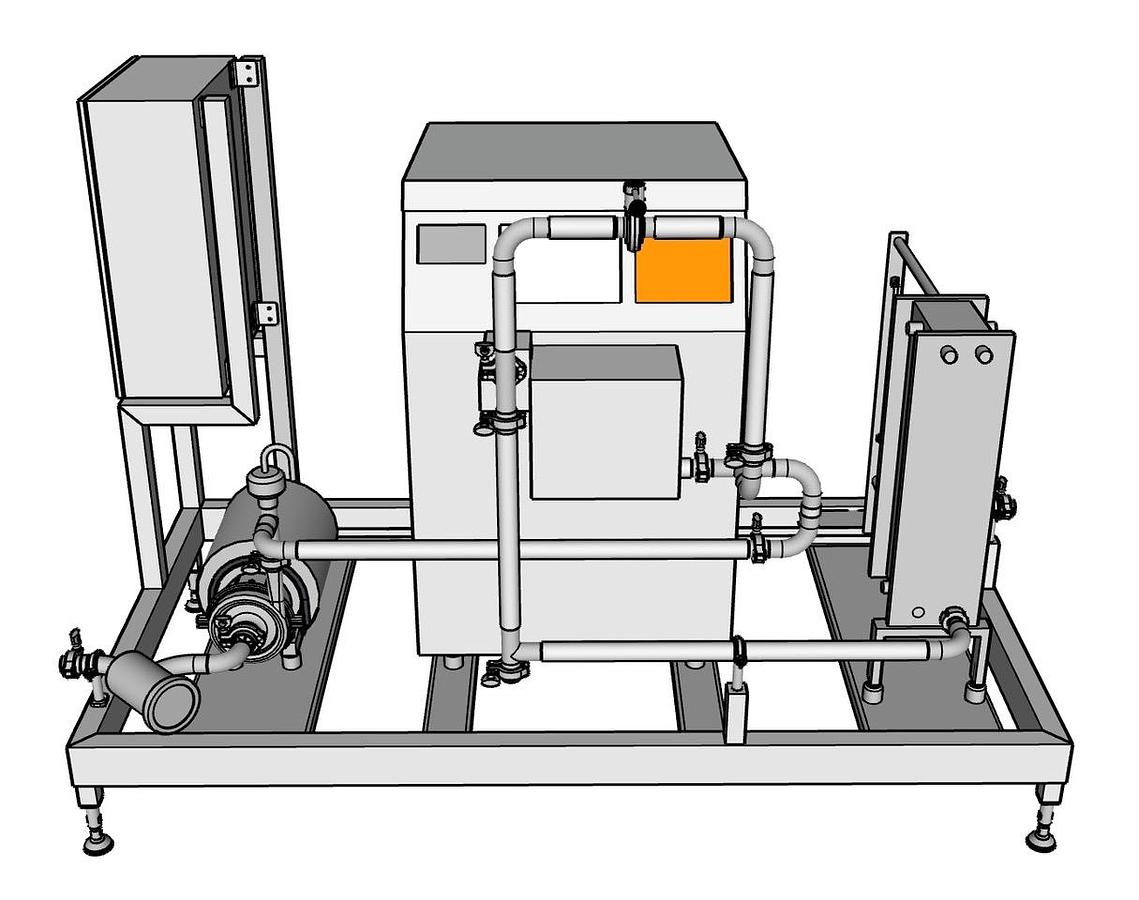

Each of our custom built ice cream plants are designed to conform to our customers specific needs. With our many years of experience and knowledge, the solutions we provide are the most energy efficient, consistent quality and produce a premium product. All components are sourced from leading global suppliers, such as Tetra Pak and GEA, and are mounted on a rigid stainless steel frame for quick, plug and play-like installation and commissioning.

For non-standard solutions please contact us. We have built customer specific plants for all types of requirements such as; cooling only, one batch heating tank, modular systems, etc.

Working Principle:

The Fincher Homogenisation and Cooling system pumps the pasteurised mix through a filter and into the homogeniser before sending it to the plate cooler, where it is chilled to approximately 4°C and prepared for transfer to your maturation tanks.

By performing the cooling outside the pasteurisation vessel, this system increases production capacity and shortens processing time. The higher-pressure homogenisation also improves product smoothness and extends shelf life.

Features:

– Integral cleaning CIP

– Temperature profile 85°C to 4°C

– Tetra Pak pump and plate heat exchanger

– GEA homogeniser, 180 BAR - single stage, with pressure transducer on the inlet

– Mounted on 100 x 50mm stainless steel frame

– Integral control panel

Specifications

| Manufacturer | FINCHER |

| Model | HOMOGENISING & COOLING SYSTEM |

| Condition | New |

| Stock Number | JB00002 |

| Capacity | Depended on requirement |

| Electrical requirements | 10kW / 400V / 50Hz |

| Ambient water requirements | 50kW / 28°C water at 3,000 litres/hour with 2 bar pressure |

| Chilled water requirements | 24kW / 1°C water at 2,000 litres/hour with 2 bar pressure |